How New Parameters and Processes Are Revolutionizing Flexible PCBs

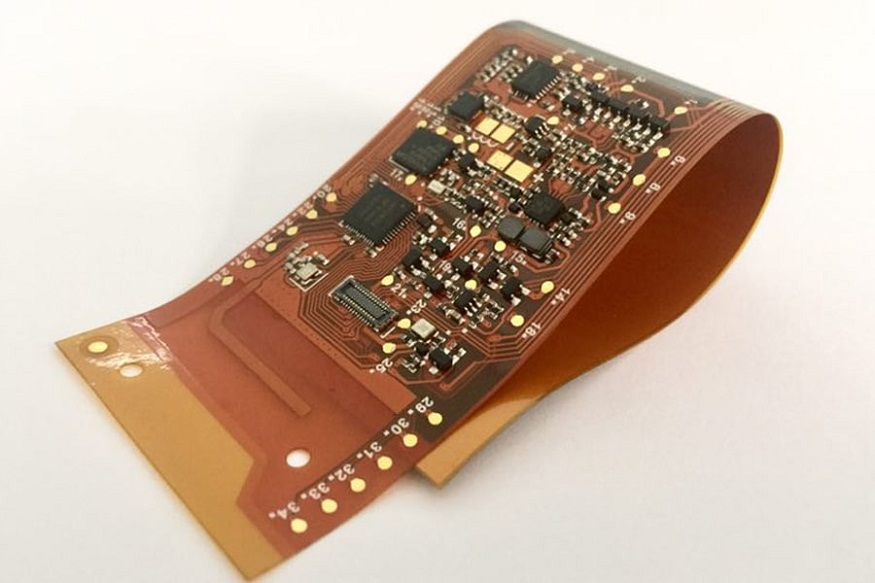

Flexible printed circuit boards or FPCBs have become very important today in many industries because their design is light, less space is required, and they can be mounted in various orientations without any difficulty. Every day as we experience technological growth, modern technology is giving birth to new parameters and processes that are enhancing more capabilities of flexible PCBs. So here are some ten key aspects detailing the exact reason why these new developments help in changing the flexible PCB design board in USA.

1. Innovations in Materials

It is quite enough to advance the technology of flexible PCBs to improve the properties of the materials they are made of. Instead of the conventional materials, the manufacturers have started using polyimide and other advanced types of plastics that are characterized by high thermal, chemical and electric insulation. The materials enable the production of FPCBs that can withstand even the harshest conditions, which is an advantage in applications where high-performance devices are needed, for instance, automotive aerospace and medical instruments.

2. Trends of Miniaturization

The miniaturization of the electronics circuit components is yet another factor that makes it imperative for more flexible PCBs to be of a much lower profile. Thanks to the new design parameters, fine trace width and small component footprint can now be incorporated within the limited area, allowing more functionality. This is very relevant when it comes to consumer electronics, wearables, and the Internet of Things because space is always a scarce resource and relates directly to the convenience and practicality of the devices about how they function.

3. Advanced Manufacturing Techniques

New manufacturing techniques that apply laser drilling, and selective plating among others have led to a great improvement in flexible printed circuit board fabrication. Because of these processes, more accurate and effective production is possible which leads to shorter production periods and reduced costs. By enabling intricate designs with high layer counts, these techniques support the growing complexity of modern electronic systems. Furthermore, these advancements allow for greater customization, enabling manufacturers to meet specific client requirements and market demands with precision.

4. Improved Signal Integrity

With the ever-growing need for high-speed data transmission, ensuring signal integrity has rather become of the essence. New processes and parameters emphasize controlling impedance at desired levels and avoiding crosstalk in stretchable printed circuit boards as much as possible. The artful manipulation of trace widths along with the application of high-end materials allows manufacturers of flexible printed circuits to design structures with great signal integrity and hence, such devices are suited for high-frequency telephone instruments or data processing equipment.

5. Embedding Passive Components

Another example of emerging practice is embedding capacitors or inductors, for example, within a flexible PCB design board as such integrations make circuits easier to design without making them increase the board sizes. Integrating these components into the flexible substrate allows for efficient yet high-performance designs. Besides saving space, this integration enhances performance by minimizing interconnections and parasitic effects. Additionally, it contributes to improved signal integrity and reduced manufacturing complexity, ultimately leading to more reliable electronic devices.

6. Improved Heat Distribution

As power handling within electronic devices increases, so does the need to effectively utilize or transfer the heat generated by such devices especially when measuring their performance and reliability. Thermal management strategies for flexible printed circuit boards have also incorporated thermally conductive materials and advanced heat-spreading techniques. These advances facilitate improved heat dissipation helping internal units maintain an operation temperature within a safe range thus increasing the shelf life of the equipment.

7. Innovations in PCB Design Techniques

The introduction of PCB design software has changed the way flexible PCBs are designed. Advanced simulation features enable engineers to evaluate and visualize complex designs before production. Such software reduces the phase of making prototypes therefore the designers can make improvements to the design in relation to the workings and the ease of manufacture of a particular product. It therefore stands to be that the timing when the product is ready to sell is vastly reduced so companies can easily accommodate market changes.

8. Goal on Sustainable Development

Similarly, social and political factors contribute to more people being environmentally aware and this in turn impacts the production of flexible PCBs. More raw material and energy-efficient processes are being adopted by manufacturers aiming at less waste. In other words, lead-free solder and other recyclable substrate materials contribute to the manufacture of less harmful flexible PCBs that can be typecasted into users as well as the markets. Furthermore, these sustainable practices not only align with regulatory requirements but also enhance the marketability of flexible PCBs by appealing to eco-conscious consumers.

9. Improvement in 5G technologies

The growth of the flexible PCB market is stimulated especially by the advent of 5G technology owing to the 5G frequency flexible PCB performance. With compact multi-band antennas and complex RF circuits, flexible PCBs have become integral in today’s ultra smartphones and mobile network architecture. The market for flexible PCB devices and components is moreover advanced due to the increasing application weight of 5G solutions entailing special materials and structural designs.

10. Increased Reliability and Durability

As flexible PCBs have begun addressing real-time mission-critical applications, their reliability and durability become even more essential. Therefore, the necessary innovations are taking place, in the form of new testing standards and quality control processes, so that FPCBs can endure extreme operating conditions, including mechanical and thermal stresses. Also, the manufacturers are embracing new sorts of testing to claim their products effective and torture tested, ensuring that flexible PCB solutions provide offers to direct the confidence towards customer usage.

Finally, the high demand for flexible PCBs can be attributed to improvements in materials, processes, and design that enhance performance, reliability and sustainability. As industries compete to produce compact, lighter and efficient electronic devices with advanced embedded system, the demand for flexible PCBs is likely to rise sharply. Therefore, by incorporating other strategies and parameters, the market players can stay ahead of the competition in this unpredictable yet fast-changing market as they come up with new offerings that meet current technological demands. The outlook of flexible PCBs appears bright given their many cases of use in consumer electronics, automotive, medical devices and telecommunications.